The Impact of Manufacturing Industry Upgrading on Automation Manufacturers

Owing to the impact of the economic crisis, the domestic manufacturing enterprises have been greatly impacted, but the impacts of various industries are not the same. Some even go against the current. Generally speaking, the enterprises with higher product technology are far less affected than those with lower product technology. Many enterprises with lower product technology even go bankrupt. It can be seen that high technology is a trend in the future. At the same time, the enterprises with high technology use more automated products and have higher requirements. In this respect, the major international manufacturers have absolute advantages with their advanced automated products, and this advantage is still irreplaceable in the short term.

_In the absence of improvement in the domestic and international economic environment, domestic manufacturing enterprises need to adopt cost-cutting measures to overcome the crisis. Therefore, as long as the performance of the automation products they use can meet the requirements, they will not pursue the brand as they used to. Therefore, from this point of view, it is self-made. An opportunity for mobile manufacturers.

Summary of Automation Manufacturers'Strategies for Industrial Upgrading

Overall, the strategies adopted by automation manufacturers in the face of China's manufacturing industry upgrading are as follows:

1. Localized production of automation products by major international manufacturers is expected to reduce the price of automation products and production costs of manufacturing enterprises.

_2. Providing integrated solutions is now mainly the success of the European and American departments in the integration of solutions, while the Japanese and Korean departments are also closely following its pace. It is difficult for domestic manufacturers to make a large integration solution because of the insufficient automation product series, but it is gratifying that some domestic manufacturers have already done so. After gradual improvement of their own automation product series, such as Huichuan, Shenzhen Stepping, etc. The implementation of integrated solutions can reduce the cost of product maintenance, matching, software compatibility, after-sales and other aspects of manufacturing enterprises.

_3. Propose a special automation product or automation solution for a certain industry, design the process of automation products for this industry, in order to achieve the highest cost performance.

4. Automation manufacturers provide flexible production for manufacturing enterprises, monitor reasonable energy consumption in a reasonable production time, so as to achieve the purpose of energy saving and efficiency, and ultimately reduce the production costs of manufacturing enterprises.

Products

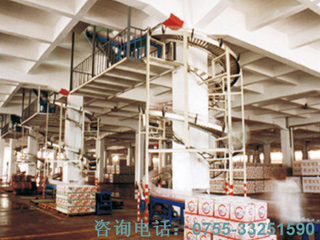

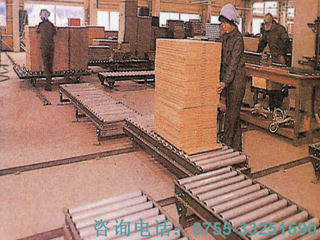

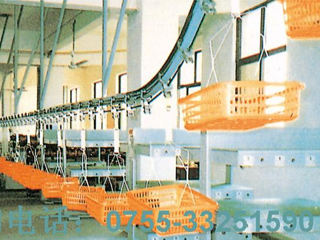

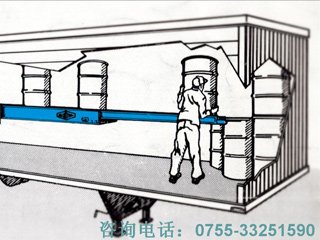

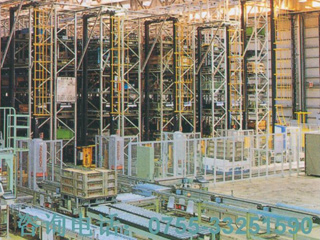

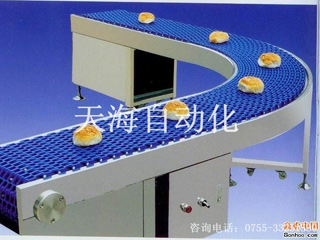

Application of Automated Logistics

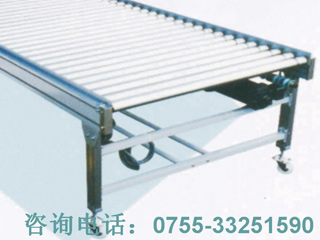

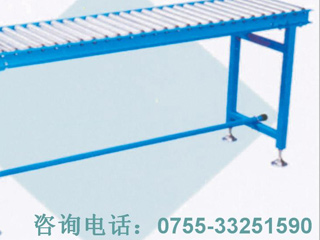

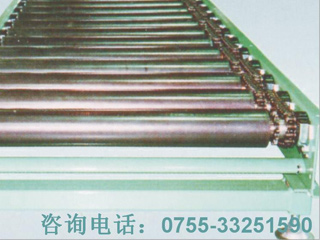

Application of Automated Logistics Logistics Transport Equipment Series

Logistics Transport Equipment Series Automation equipment

Automation equipment Balancer

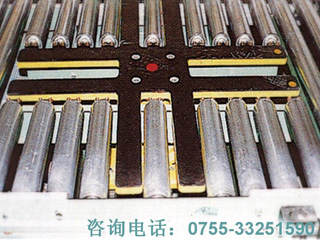

Balancer Other conveying equipment

Other conveying equipment Equipment accessories

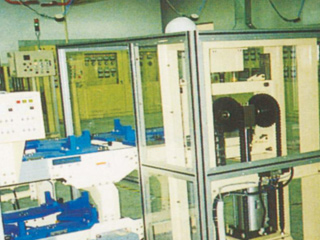

Equipment accessories Control system

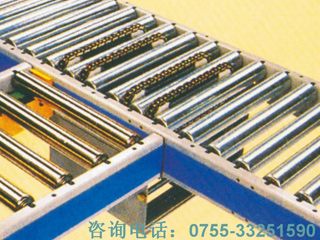

Control system Roller

Roller Other industries

Other industriesYou Are Here:Home > News > Company News

News

The Impact of Manufacturing Industry Upgrading on Automation Manufacturers

Release time:2019/9/9 18:39:39